Stainless steel blasting media - the efficient alternative to glass beads

Looking for a high-quality alternative to glass beads for blasting? FINAL® stainless steel blasting media offers the perfect replacement. Providing a comparable satin-matte surface finish, but with significantly longer media lifespan, minimal dust, and much lower operating costs, FINAL® is the efficient and cost-effective replacement for glass beads. Unlike glass beads, which quickly break down due to brittleness and create unstable media mixes and dust, FINAL® features a durable stainless steel structure that maintains its shape and performance over multiple cycles – with consistent roughness and uniform surface appearance.

Which is Better: Glass Beads or Stainless Steel Blasting Media?

In surface blasting, the properties and performance of the blasting media are critical, as they directly impact surface quality and process costs. There are important aspects to consider when making a selection, such as the blasting effect, blasting performance, service life, cleanliness and environmental friendliness. An abrasive must therefore satisfy many criteria in order to be considered optimal.

When choosing blasting media, key factors include blasting effect, performance, durability, cleanliness, and environmental friendliness. The media must meet several criteria to be considered optimal. For finishing stainless steel surfaces, both glass beads and stainless steel media like FINAL® are commonly used. While results may look similar, the operating behavior differs significantly.

Both media types are suitable for removing surface imperfections from prior processes such as deburring, grinding, or scotching, and for eliminating heat tint or weld discoloration. They also produce a satin-gloss finish with high visual appeal.

Glass Beads vs. Stainless Steel – Two Proven Blasting Media with Different Performance

Glass beads are naturally brittle and break easily. Due to their fragility, they degrade quickly and lose grain size rapidly. This leads to unstable media mixes and inconsistent blasting results, while also producing large amounts of dust and waste.

FINAL® is made from a tough stainless steel alloy, making it extremely durable and impact-resistant. It retains its shape and grain size for much longer than glass beads. Wear occurs only gradually.

FINAL® offers simple handling, stable blasting performance, and consistent surface results with reliable roughness levels and a uniform finish.

Practical example: The use of FINAL® instead of glass beads results in the following savings:

Example: Mechanical engineering in the food industry

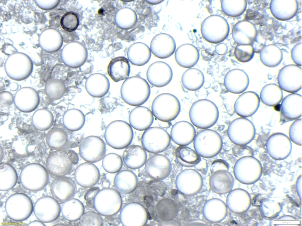

Comparison of the decomposition of the abrasives

A direct comparison shows that glass beads wear out after just a few runs, whereas FINAL® remains consistently efficient over many uses.

FINAL® offers a significantly longer service life, reducing operational costs and increasing process reliability.

Stainless steel blasting media like FINAL® delivers a comparable surface finish to glass beads but is significantly more durable, efficient, and low-dust – ideal for industrial surface treatment applications.

FINAL® vs. glass beads - advantages & properties in comparison

FINAL®, the high-quality stainless steel abrasive from VULKAN INOX, offers a number of advantages over glass beads - both technically and economically:

REUSABILITY & SERVICE LIFE

FINAL®: Long service life, reusable (up to 1000 cycles)

Glass beads: Fast wear, significantly shorter service life (approx. 4 cycles)

DUST DEVELOPMENT & PLANT WELDING

FINAL®: Extremely low dust load → less filter load, less maintenance required

Glass beads: Increased dust generation, higher system wear

BLASTING PATTERN & CONSISTENCY

FINAL®: Technically clean, reproducible blasting pattern even after several uses

Glass beads: Visually appealing, matt finish, but with diminishing quality when reused

ECONOMIC EFFICIENCY & PROCESS RELIABILITY

FINAL®: Lower consumption costs due to long service life, stable process

Glass beads: Higher consumption and refill requirements → higher running costs

SUSTAINABILITY & DISPOSAL

FINAL®: Fully recyclable, significantly lower waste volumes

Glass beads: Rapid material loss, higher volume of waste

Your advantages-your added value: FINAL®

FINAL®, the high-quality stainless steel abrasive from VULKAN INOX, offers numerous advantages over glass beads - both technically and economically:

FINAL® ensures a clean, efficient blasting experience: thanks to its extremely low dust generation, the stainless steel abrasive makes a decisive contribution to a safe and healthy working environment. At the same time, significantly less waste is produced, which reduces disposal costs and makes the entire process more economical.

The result: low-dust blasting with minimal machine wear and consistently high surface quality.

Conclusion: Switching to FINAL® is also worthwhile in the long term!

Frequently Asked Questions About Glass Bead Alternatives

Which is Better – Glass Beads or Stainless Steel Blasting Media?

FINAL® stainless steel blasting media produces a comparable finish to glass beads, but is more durable, efficient, and generates significantly less dust.

Is There an Eco-Friendly Alternative to Glass Beads?

FINAL® is reusable, produces less waste, and supports a resource-efficient blasting process.

How Many Times Can FINAL® Be Reused?

Thanks to its toughness, FINAL® maintains its shape over many blasting cycles – significantly reducing media consumption and operational costs.

Is the Surface Finish Truly Comparable with Glass Beads?

FINAL® creates a satin-matte finish virtually indistinguishable from that of glass beads – with more consistent and reliable results.