THE HARDEST AND FASTEST

With the sharp-edged GRITTAL GH, surfaces are cleaned and roughened quickly. Because with the hardest blast media, you achieve the highest blasting speed and the best possible surface preparation, and that in all industrial blasting processes.

Extra hard and efficient

Its special alloy and subsequent heat treatment makes GRITTAL GH a particularly hard and powerful blast abrasive. Its sharp-edged shape is retained even after many blasting cycles and ensures an ideal surface profile with a high peak number.

The blasted surfaces are homogeneously roughened and optimally cleaned. In this way, even the highest demands on surface preparation are met.

High economic efficiency

And although GRITTAL GH is designed for highest abrasion performance, its hard-tough alloy gives it an exceptional lifetime. Paired with its high weight, GRITTAL GH thus achieves a very high blasting power, allowing you to realize your blasting processes quickly and with little effort.

Versatile

As a high-performer, GRITTAL GH easily handles a variety of blasting tasks on a wide range of materials.

- Heavy descaling and cleaning

- Roughening and surface preparation

- Matt surface finishing and structuring

- High-alloy and low-alloy steels

- Aluminum, bronze, brass and zinc

- Titanium and nickel-based alloys

Dust-free and less waste

While other blast abrasives break quickly during blasting and generate a lot of dust in the process, high-strength GRITTAL GH remains form-stable for a long time. This noticeably improves working and viewing conditions and minimizes abrasive-related waste and disposal costs.

Reduced blast media consumption

Its break resistance is particularly convincing in direct comparison with garnet sand or corundum, which are extremely hard and brittle. Thus, their users can reduce their previous blast abrasive consumption to 2-4% with GRITTAL GH.

Large area performance with minimal energy consumption

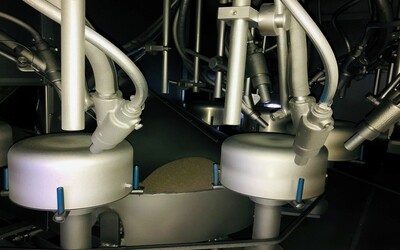

At the same time, its long grain integrity allows the user a blasting process with low work and control requirements. This is because the roughness values and cleanliness levels achieved are very constant and easily reproducible. In contrast to mineral abrasives, GRITTAL GH can also be used in wheel blast machines. High quantities and large area outputs are thus realized particularly economically and with minimal energy consumption.

Reusable and thus resource-saving

Manufactured from high-quality input materials, GRITTAL GH is 100% recyclable. Its long durability and complete recyclability make it a resource-saving and sustainable blast media in a modern circular economy.

Download

Grain classes