Normal corundum - Aluminum oxide-based abrasive

Normal corundum is a reusable blasting agent based on α-aluminum oxide. The sharp-edged blasting agent is versatile and, thanks to its titanium oxide content, slightly tougher and more durable than high-purity precious corundum. Its hardness is exceptional—it is the fourth hardest material after diamond.

Advantages and disadvantages of corundum

HIGH PERFORMANCE – HIGH CONSUMPTION

Normal corundum is a mineral blasting agent with high removal capacity and abrasive effect. Its extreme hardness and polygonal shape make it a very aggressive and powerful blasting agent that intensively roughens and cleans surfaces. This enables high surface outputs, but also the blasting of workpieces and surfaces that are themselves very hard. Like all ceramic materials, normal corundum is hard and therefore brittle. Due to its lack of toughness and deformability, it reacts very quickly to impact stress with brittle fracture and material failure. Grain disintegration begins after just a few blasting cycles and progresses rapidly, while angular stainless steel abrasives fatigue and wear only very slowly.

The high-speed grain disintegration of corundum leads to a high breakage and degradation rate, so that it quickly becomes fine-grained during blasting and reaches its wear limit in a very short time. For technically and economically stable blasting, the worn abrasive must therefore be removed and replaced promptly, which is associated with high consumption and waste quantities.

A comparison between corundum and stainless steel abrasives makes the differences clear:

LOTS OF DUST AND WASTE

When blasting with standard corundum, large quantities of dust and fine dust are released because the grain fragments quickly into tiny particles. This results in high concentrations of airborne dust and intense dust deposits, which can severely impair and disrupt the blasting work, the blasting result, and the process environment. The massive amounts of dust and waste require a powerful filter system that achieves an air exchange rate of at least 80 times and at the same time has a generous filter area to keep the filter surface load low.

Normal corundum has a material loss rate of 5% to 10% per blasting cycle, which corresponds to 10 to 20 possible blasting cycles. With a blast pot throughput of 600 kg per hour, this results in a considerable 30 kg to 60 kg of dust, waste, and consumption. Performance-oriented blasting processes that are carried out with high blasting intensity or require large quantities and high surface outputs are therefore associated with considerable costs and environmental pollution.

The negative " " cascade , which is triggered by low breaking strength and service life, can be eliminated by using an angular stainless steel abrasive. A well-thought-out choice of abrasive not only saves costs, but also noticeably and comprehensively improves cleanliness: during blasting, on the surfaces and throughout the entire workplace.

ALWAYS SHARP AND AGGRESSIVE

Normal corundum is brittle, highly abrasive, and is preferred for work that requires maximum material removal, such as cutting, grinding, or blasting. This makes normal corundum an extremely sharp and very versatile blasting agent that quickly cleans and intensively roughens substrates.

However, its aggressive blasting behavior is associated with equally aggressive wear behavior that continues until the end of its service life. In addition to its high hardness, its special breaking and splintering behavior plays an important role, as it repeatedly produces new fragments with sharp cutting edges. The highly abrasive wear effect occurs wherever the fragments grind along with high frictional force. Blast nozzles, blast and conveyor hoses, and centrifugal separators (cyclones) are particularly affected by this. Highly wear-resistant boron carbide blast nozzles with standard corundum achieve service lives of 400 to 500 hours. In contrast, angular stainless steel abrasives achieve 1,500 to 2,000 blasting hours, and experience has shown that the service life of the blasting hoses is tripled.

PRESSURE BLASTING OR TURBINE BLASTING

The extremely high wear on blasting media and system technology limits the use of corundum to blasting systems that use compressed air as the carrier and acceleration medium. In high-throughput centrifugal wheel blasting systems, which accelerate and eject large quantities of blasting media electromechanically in an "airless" manner and thus offer significant performance advantages, the use of standard corundum is not recommended for technical and economic reasons. The combination of centrifugal wheel technology and stainless steel abrasives enables the user to significantly increase productivity and reduce operating costs, provided that the parts to be blasted have a simple geometry and are easily accessible for the abrasive.

AREAS OF APPLICATION

Normal corundum is used as a blasting medium for a wide range of blasting tasks on a wide variety of materials:

Blasting tasks:

- Cleaning and roughening

- Rust and scale removal

- Casting cleaning and desanding

- Paint and coating removal

- Deburring and rounding

- Matting

Application:

- Low- and high-alloy steels

- Non-ferrous metals

- Concrete and natural stone, ceramics

- Plastics and composite materials

- Glass and wood

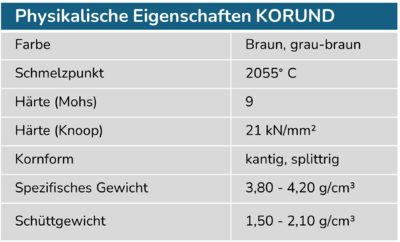

PHYSICAL PROPERTIES

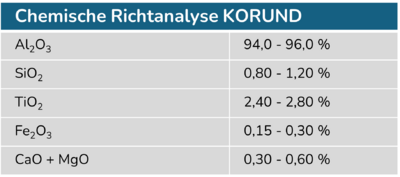

CHEMICAL ANALYSISC

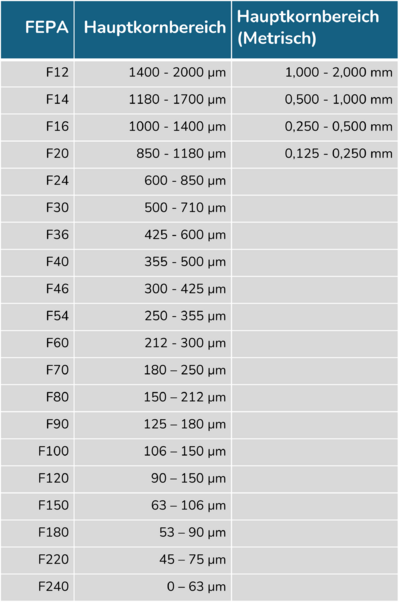

GRAIN SIZES

Brown normal corundum is classified according to the European standard FEPA F for abrasive bodies, but is also available in metric dimensions.

MANUFACTURE

Synthetic normal corundum is obtained from calcined bauxite rock with a high aluminum oxide content. The aluminum oxide is extracted from the bauxite in an electrothermal reduction process. Melting takes place at temperatures above 2000°C in electric arc furnaces and is therefore very energy-intensive. Due to its manufacturing process, normal corundum belongs to the electrocorundum (ELK) family.

Other bauxite companions in the corundum melt, such as iron oxide and silicon oxide, are also reduced by the addition of coke and iron filings and settle as ferrosilicon at the bottom of the furnace. The ferrosilicon is used to produce normal corundum FeSi, which consists of a mineral component of normal corundum and a metallic component of ferrosilicon.

The molten corundum is then poured into molds to cool and solidify over several days. The corundum blocks are crushed into granules in crushers and mills and undergo further purification steps. The corundum is then screened and classified according to grain size.